What is a carbon footprint?

The carbon footprint describes the emissions generated by the company's operations and their impact on the climate. Calculating an organization's carbon footprint means calculating greenhouse gas emissions generated through operations. The unit of the carbon footprint is a carbon dioxide equivalent, which reflects the climate-warming effect of various greenhouse gases converted into the equivalent effect of carbon dioxide in the atmosphere.

For example, one kilogram of carbon dioxide emissions (CO2) corresponds to one kilogram of CO2 equivalent, while one kilogram of nitrogen oxide (NO2) corresponds to almost 300 kilograms of CO2 equivalent.

This calculation is based on the guidelines of the Greenhouse Gas Protocol. The GHG protocol is a standard published by the World Natural Resources Institute (WRI) and the World Business Council for Sustainable Development (WBCSD) in 1998, which is used for reporting globally. The protocol is aimed at companies, governments and other actors for carbon footprint measurement and reporting.

The GHG protocol defines the limitation and calculation of certain emission sources. Uniform demarcation and calculation principles ensure that the calculation results are accurate and reliable. The standards oblige companies to report at least their Scope 1 and 2 emissions. The calculation of Scope 3 emissions is voluntary, but recommended. The Scope emission classification is explained in more detail on this page.

Calculation

Carbon footprint management starts with identifying emission sources and finding out the amount of emissions caused by the operation. With the help of the calculation of the carbon footprint, it is possible to map the largest sources of emissions, so that measures to reduce emissions can be targeted correctly.

This calculation provides information on the carbon dioxide emissions of Atex's business operations. With the help of the results of the calculation, the company can develop its operations in an even lower emission direction in the future. Based on the calculation, the amount of emissions compensation needed for carbon neutrality is also seen. The report contains the carbon footprint of Atex Workwear's operations from 01.01.2023 – 31.12.2023, presented as carbon dioxide equivalents (CO2e). Carbon dioxide equivalent means the combined measured environmental impact of different greenhouse emissions. The calculation made from the figures of 2023 is the company's first carbon footprint calculation, and the results of this calculation will be used as a reference year in the following calculations.

In calculating the carbon footprint, the company's consumption readings of different emission sources and location-specific emission factors from 01.01.2023 to 31.12.2023 have been used.

Read the entire carbon footprint report by clicking on the icon.

COMPANY'S DIRECT EMISSIONS

Scope 1 – The organization's direct emissions

Property owned by the company, which includes the company's own energy production and the fuel consumption of its own or controlled vehicles.

INDIRECT EMISSIONS OF THE COMPANY

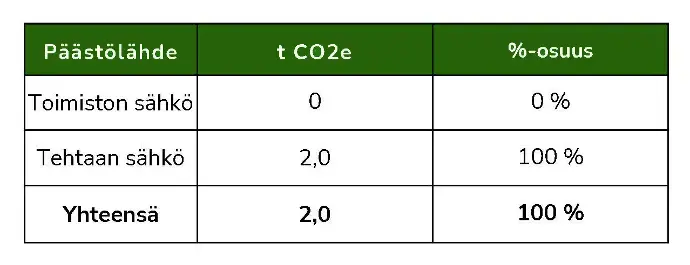

Scope 2 – Indirect emissions of the organization

Electric energy and heating and cooling energy purchased by the company.

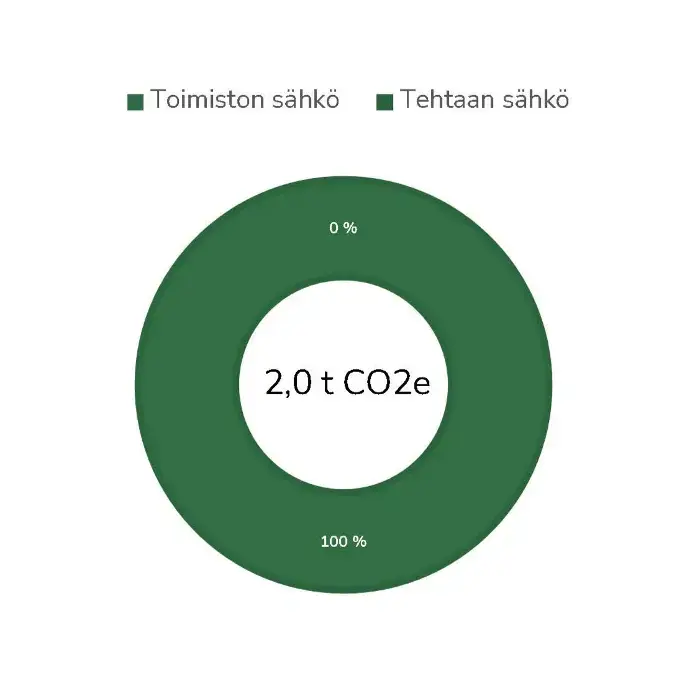

Atex Workwear's scope 2 emissions consist of the electricity consumption of the office in Porvoo and the factory in Lithuania.

VALUE CHAIN EMISSIONS

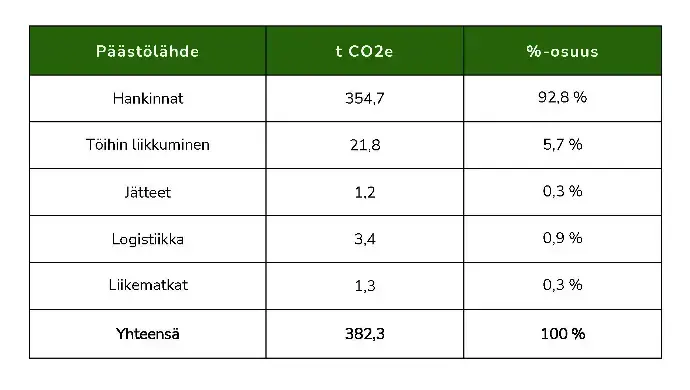

Scope 3 – Value chain emissions

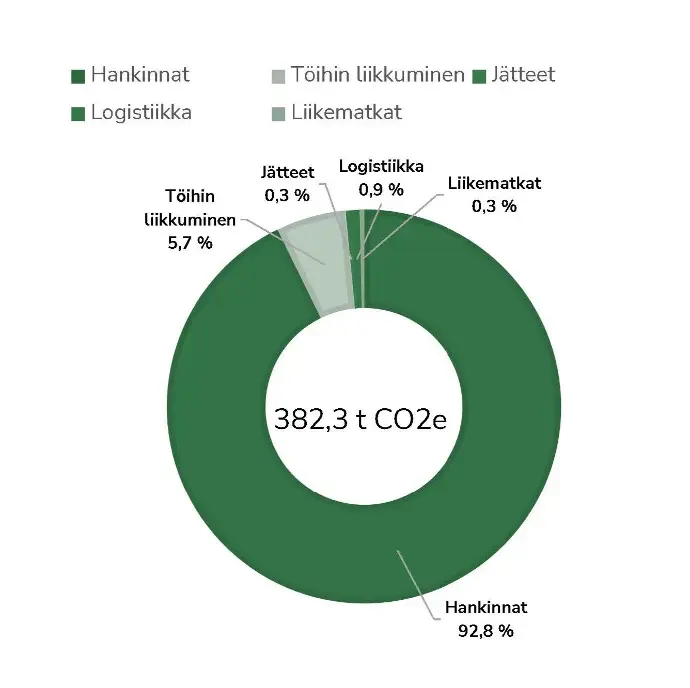

The emission calculation of the value chain covers the emissions of business operations from subcontracting to the customer. The scope 3 emissions of Atex Workwear include procurement, logistics, waste, business trips and traveling to work.

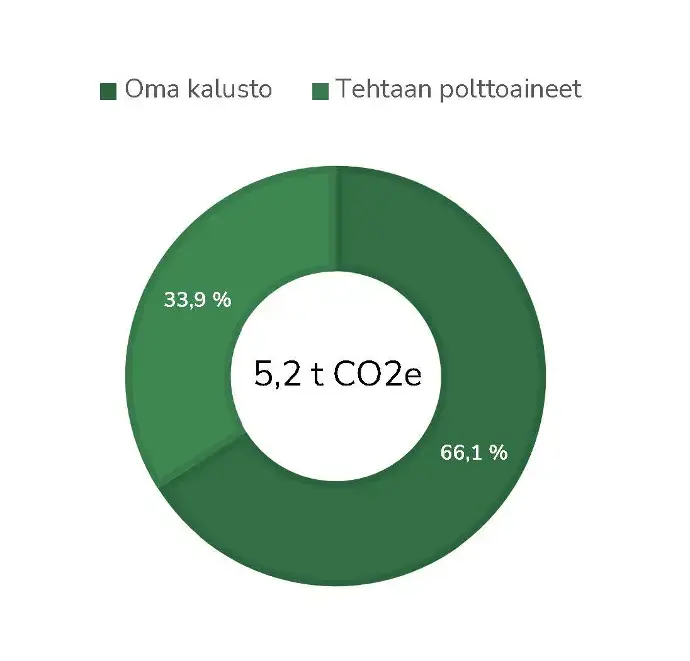

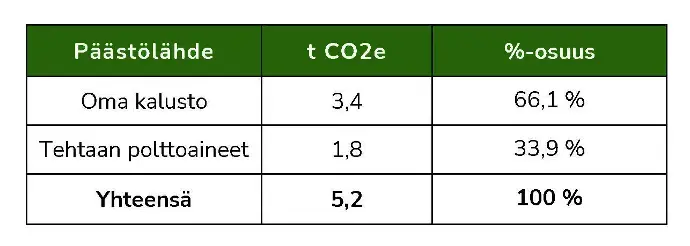

The scope 1 emissions of Atex Workwear consist of the fuels of our own cars and the fuels of the Lithuanian factory.

The emission calculation of Porvoo's own fleet is based on liters of fuel. The company has at its disposal a gasoline and diesel truck, as well as an electric forklift and a stacker. The fleet's electricity consumption is included in scope 2 emissions.

The Lithuanian factory's fuel emissions are based on fuel consumption in euros. The factory is heated by burning wood, which does not produce direct emissions.

Atex Workwear's scope 2 emissions consist of the electricity consumption of the office in Porvoo and the factory in Lithuania.

In Porvoo, Porvoon Energia's electricity is used, the origin of which is 48.2% nuclear power and 51.2% renewable, i.e. the electricity is emission-free. The electricity consumption reported by Porvoon Energia in the reporting year was 83.5 MWh. During 2023, solar panels have been put into use in Porvoo, which means that part of Porvoo's electricity will be produced with solar energy. The electricity produced by the solar panels is emission-free.

The Lithuanian factory's electricity emissions are based on a kWh estimate of electricity costs in euros. The specific emission factor according to the residual distribution of Lithuania has been used as the emission factor.

93% of the company's scope 3 emissions consist of purchases, which include fabric purchases from own production. The emission calculation for purchases is based on the quantity and material of the fabrics.

Scope 3 emissions are detailed in more detail in the carbon footprint report.

Because we care.

The well-being of the environment and people is extremely important and valuable to us.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.