Our ethical and ecological values

At the center of our company's product development are a long life cycle and the energy efficiency of maintenance. A long-lasting product that can be maintained at the lowest possible washing temperature supports our goal of sustainable development.

About our operation

Established in 1992, ATS - Ammattityökalut Oy is a company specialized in the design, manufacture and sale of workwear and EN standardized protective clothing. Our own brand is ATEX WORKWEAR. We are also an importer of protective clothing and accessories. In addition to professional clothing, the company's product range includes safety shoes, tools and club products.

The focus of the company's product development is a long life cycle and the energy efficiency of maintenance.

A long-lasting product that can be maintained at the lowest possible washing temperature supports our goal of sustainable development.

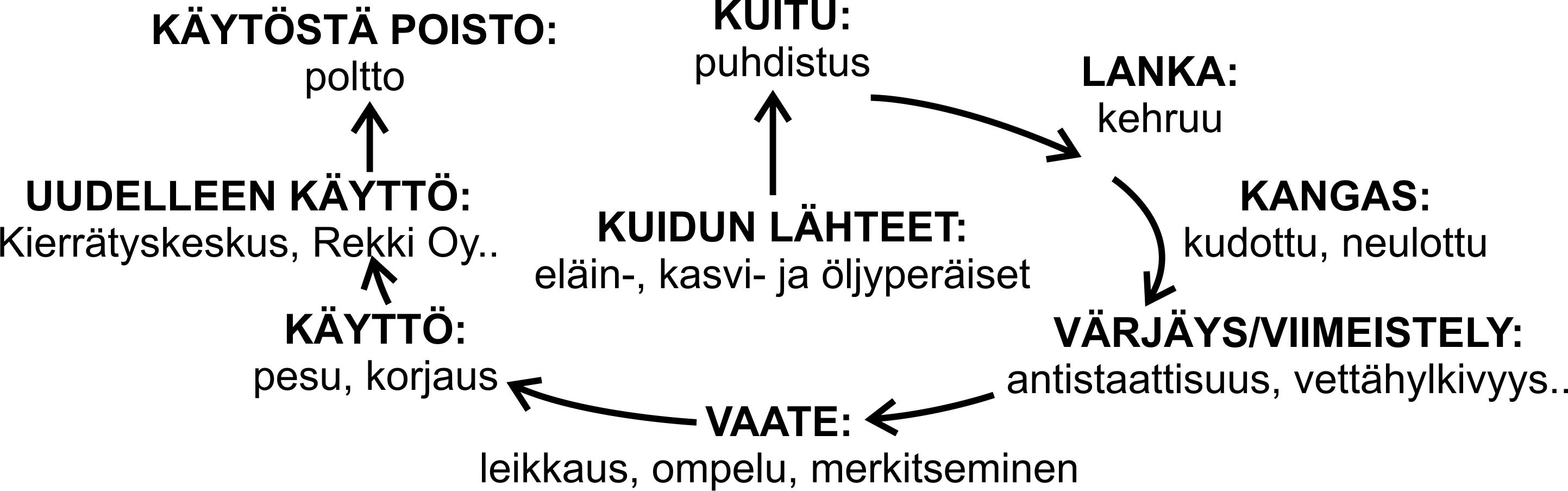

The life cycle of a garment consists of cleaning the fiber, spinning the yarn, weaving or knitting the fabric, finishing the fabric, cutting the fabric, sewing the garment and marking the product eg printing, delivery, use, maintenance and finally reuse or disposal. Product maintenance has a significant impact on the environment. ATS - Ammattityökalut Oy 's own branding begins with the purchase of finished material and after production and storage ends with delivery to the customer. We also service the products and arrange for decommissioning.

Product life cycle as a diagram:

The fibers we use are mainly cotton and polyester. Most of our products consist of a mixture of these fibers and various surface treatments. When comparing acrylic, viscose, polyester, cotton and wool with respect to the water and energy resources required to produce fibers, the highest consumption of water and polyester by irrigated cotton. In terms of energy consumption, the polyester is placed in the middle of the strip and the cotton just below it. The best option always depends on the application. All the materials we use are certified by Öko Tex. Our material choices for standard protective clothing determine the requirements of EN standards.

Our products are manufactured either in our own workwear factories in Estonia and Lithuania or outsourced in Europe and Asia. At the sewing companies we use, our products are manufactured under safe, fair, legal and humane conditions. The factories comply with the provisions of the ILO Conventions and the UN Convention on the Rights of the Child in the manufacture of products.

Our company belongs to the Finnish Association of Occupational Safety and Health ( STYL ), whose work group our representative sits on. STYL, on the other hand, is a member of the European Occupational Safety and Health Organization (ESF).

To reduce travel distances, products made in Europe are sewn from European standard materials and supplies and products manufactured in Asia are made from locally sourced materials and supplies. Our products are transported within Europe by truck in bulk, while deliveries from Asia are by ship and rail.

Promoting environmentally efficient solutions and respecting environmental values are part of the company's core values. Mapping the environmental impacts caused by business operations and finding ways to reduce them has been raised as a special review. Our new premises have been built to be energy efficient, however, the biggest of the concrete measures is moving production to an increasing extent from Asia to Europe.

For the most part, our work and protective clothing should be disposed of as mixed waste after use. The mixed waste from our own Porvoo site is burned at Vantaa Energia's waste power plant or at Kotka Energia's utility power plant. Cutting waste from our factories is delivered to local power plants. District heat and electricity are produced from mixed waste. Our products do not create landfill waste.

The disposal of the disposable protective coveralls we represent is classified as hazardous waste if they have been treated with dangerous chemicals or asbestos. Otherwise, they also qualify as mixed waste.

A clean, intact or unused product can be recycled for reuse, due to the technical finishes the products are not suitable for scrap.

The cornerstones of quality management

-

Motivated, competent and committed personnel

-

Efficient operational processes

-

Continuously developing quality management system

-

Efficient supply chain

-

Long sustaining supplier relationships

Environmental management

-

Management that includes environmental issues in strategies

-

Monitoring and Compliance with Applicable Legislation

-

Reducing the carbon footprint of logistics solutions

-

Increasing the energy efficiency of our operating environment

-

Improving recycling and sorting

Our promise

"We focus on energy-efficient and long-life products. Our goal is to achieve high-quality sustainable development by caring for both people and the environment."

In Porvoo 2nd of March 2020

Jari Toivonen

CEO

ATS – Ammattityökalut Oy

Raudoittajantie 16, 06450 Porvoo, FINLAND